Sewage Treatment Plant [STP]

The major aim of Sewage treatment plants is to remove as much of the suspended solids as possible before the remaining water, called effluent, is discharged back to the environment. We use water in our daily life for almost everything such as cooking, washing, bathing, toilet, etc. If we recycle water for these purposes, demand for fresh water can be reduced. Therefore, it is important to treat sewage and reuse this treated effluent for washing, floor cleaning etc.

We Design, Fabricate, Supply, Erection and Commission Sewage Treatment Plants (STP) for treating sewage generated by Industry, large colonies, Hotels, Hospitals, IT Parks and commercial buildings.

By using our Innovative solution -ODOBAN- delivers the 100% organic methods of physical and biological process to remove the color, odor and contaminants in the waste water.

HOW?

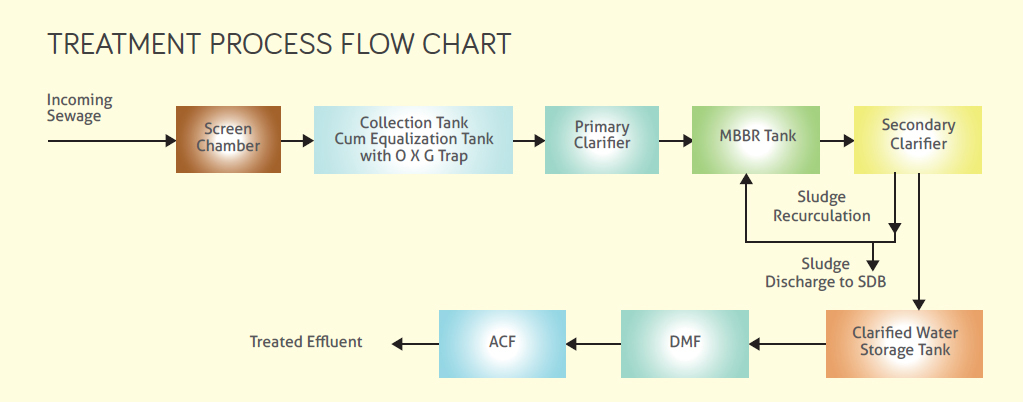

TREATMENT PROCESS FLOW CHART

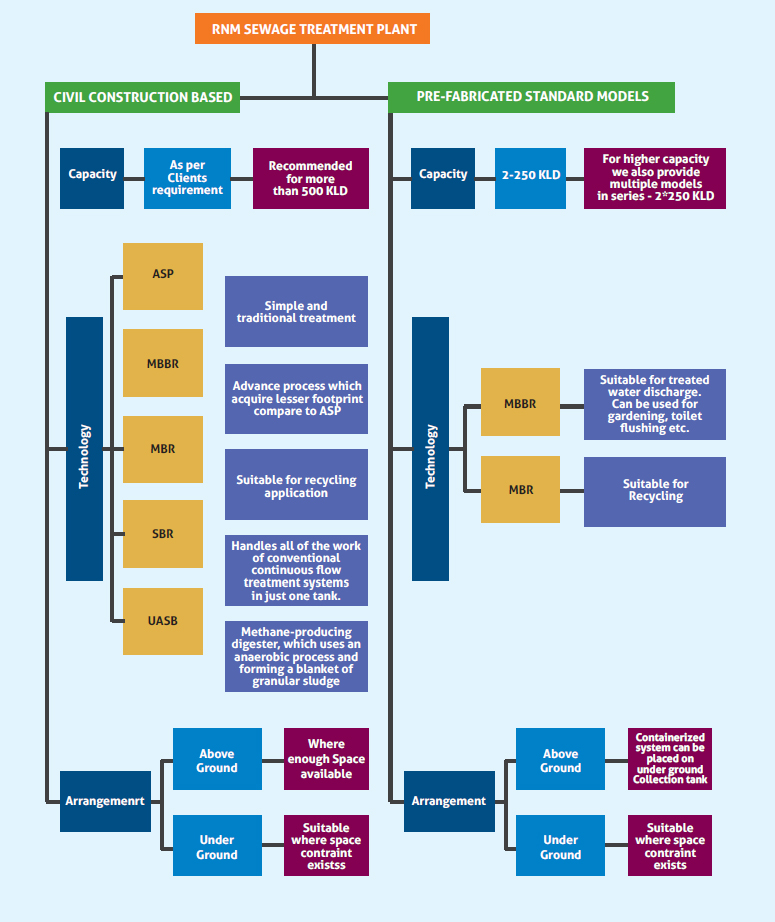

Depending on the design criteria, several types of biological processes may be used. The technologies nowadays used are as mentioned below:

ASP

Activated Sludge Process is most commonly used suspended growth aerobic process. In this process, organic matter present in the wastewater is aerated so that micro-organisms metabolize the soluble and suspended organic matter. Part of the organic matter is synthesized and form new cells and part is oxidized into CO2 and water to derive energy. The new cells formed are removed in the settling tanks and part of this settled biomass is returned to the aeration tank. The remaining is removed as excess sludge.

MBBR

Moving Bed Biofilm Reactor(MBBR) technology is an attached growth aerobic process which is based in biofilm principle. Here the bacteria grow on plastic media carriers which are kept in suspension and in continuous movement with the help of aeration or mixing.

MBR

Membrane Bio Reactor is a combination of activated sludge biological process with a physical separation using membranes which are submerged into tank. This bioreactor incorporates activated sludge process and micro or ultrafiltration clarification based on membrane technology which produces treated water quality that can be utilized to reuse/recycle.

UASB

Anaerobic treatment is carried out in the absence of Oxygen which leads to conversion of organic matters into CH4 and end products like CO2 and NH3. Upflow Anaerobic Sludge Blanket (UASB) system uses granulated bacteria which are contacted to organic components present in the wastwater. Methane gas is produced due to decomposition of organic components. With the help of Gas liquid-solid separator (GLS), gas, liquid and granules are separated.

SBR

The Sequencing Batch Reactor (SBR) is a non-steady state activate sludge process which operates into batch mode with aeration and sludge separation occurring in the same tank. This process does not require separate equalization and primary sedimentation basins.

SELECTION PROCESS

PROCESS DESCRIPTION

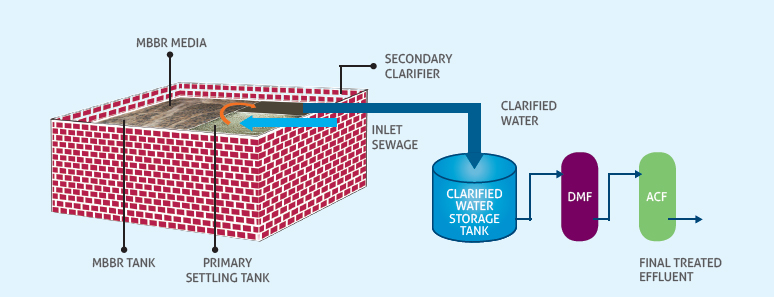

R N M Pre-Fabricated Models – Process Description

SEWAGE TREATMENT INVOLVES:

The removal of solids by physical screening or sedimentation. The removal of soluble and fine suspended organic pollutants by biological oxidation and adsorption processes. Both forms of treatment produce sludge as by-products and these have to be treated and used or disposed of in an economical and environmentally acceptable way. The following describes a typical sewage treatment sequence which is illustrated in above Fgure. In practice, there are many process variations employed according to locality and the standard of effluent required.

PRIMARY SETTLEMENT

Primary settlement is in accordance with Indian Standard, giving the required hydraulic retention time and ensuring that 30% of the BOD will settle out in the primary tank. CLEANCON PLANTS below 500 persons will have sludge storage integral to the primary tank. Above 500 persons it may become more cost effective to provide separate sludge storage and / or digestion.

The primary settlement tank is equipped with unique Tube Settler media to prevent floating scumentering the biologiacal phase of the treatment process. It also incorporates CLEANCON’S unique forward feed system which lowers the level in the tank, during periods of low flow, to provide a buffering capacity for possible surges in the influent. The forward feed also mitigates process risks associated with variable loads.

BIOLOGICAL TREATMENT

After primary settlement, the settled liquor flows to the biological treatment unit by displacement and via the air lift forward feed. The biozone is fully segment is filled with high voidage plastic filter media, where both carbonaceous and nitrifying processes take place. Air to oxygenate the influent and to scour excess biomass from the filter media is introduced continuously below each chamber by a series of diffusers.

FINAL SETTLEMENT

Followign biological treatment, the effluent flows into the final (humus) settlement tank having Tube Settler media where, the excess biomass settles out. The humus tank is equipped with air lifts which are arranged to automatically transfer settled humus sludge to the primary tank for co-settlement. The treated effluent flows under gravity to the works outfall.

R N M PRE-FABRICATED MODELS

R N M has developed standardized models based on MBBR and MBR Technologies, which are the most advanced state of the art technologies nowadays.

TECHNOLOGIES

MBBR TECHNOLOGY

Moving Bed Biofilm Reactor (MBBR) technology is based on the biofilm principle, which uses microorganism for biological treatment of wastewater.

With this application we offer advanced wastewater treatment solutions for the industrial and municipal markets. These solutions significantly increase the capacity and efficiency of existing wastewater treatment plants, while minimizing the size of new plant deployments.

MBR TECHNOLOGY

This process combines a biological treatment using activated sludge with a physical separation treatment using submerged membranes (instead of secondary clarigier).

Combined treatment consists of combining several stages of treatment in package units called membrane bioreactors (MBRs). These bioreactors incorporate activated-sludge biological treatment as well as ultrafiltration-membrane clarification to produce effluent that can be discharged into sensitive areas or re-used.